hardness test weld|fracture test for fillet weld : dealers Discover the welding hardness test's role in ensuring weld quality, structural integrity, and process optimization. Learn about machinery, preparatory steps, and test outcomes for .

webu/joaocarlos1246. • 9 days ago Bibi Vitona. 49. u/Ccaiu. • 11 days ago Todo mundo olha pro mesmo lugar, quando ela posta foto nova 👀🤤🔥🔥. 93 7. u/Ccaiu. • 11 days ago Alguém puxa .

{plog:ftitle_list}

Gastronomia - Vert Motel - Mossoró

Hardness is one property of a completed weld, heat-affected zone, or unaffected base metal that may be analyzed. Why Test Hardness. Hardness is an indicator of metal . When it comes to hardness testing welds, benchtop models are used inside factories, especially if needing to certify parts. Portable hardness testers are often used for checking flat and round structural pieces in the field. .

Hardness testing is a quantitative test method. In metallurgical science, the hardness value of a material is directly related to the type of microstructure. Ferrite is softer .

The Vickers hardness test is widely used for testing welds because the size of the indentation is small and it is easy to locate in specific regions of the weld such as weld metal, HAZ and base metal. Standard Methods for Mechanical Testing of Welds. Key Words—Mechanical tests, bend tests, nick-break tests, shear tests, tension tests, fracture toughness tests, fillet .Discover the welding hardness test's role in ensuring weld quality, structural integrity, and process optimization. Learn about machinery, preparatory steps, and test outcomes for .

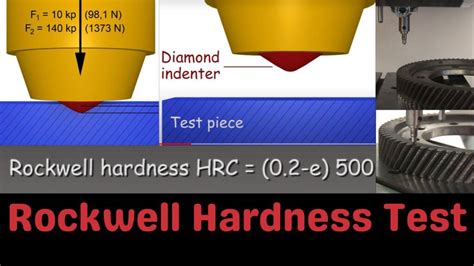

1 Rockwell Hardness. The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth .

Here you will find general practical tips on hardness testing as well as useful information on the most common hardness testing applications such as progression measurements (CHD, NHT, RHT), hardness mapping, weld .

Testing of Welds AWS B4.0M:2000 An American National Standard. 550 N.W. LeJeune Road, Miami, Florida 33126 AWS B4.0M:2000 An American National Standard . fillet weld tests, stud weld tests, hardness tests, weldability tests, groove weld tests, soundness tests, nick-break tests. v Table of Contents Page No. Hardness testing can be applied to various types of materials, some of which are listed below: Metals and alloys. Ceramics. Elastomers. Polymers and plastics. Films. Rocks and minerals. Importance of Hardness .

A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .When hardness testing of welds, a series of measurements are made in a given pattern at a specific distance from the sample edge or top of the weld. The progression of the hardness values can then be plotted in a graph. Methods typically used: HV5 and HV10 ; Applicable standards: ISO 9015-1/-2 ; Mapping of hardness test results of cold weld (MC time = 5 ms), good weld (MC time = 30 ms), and hot weld (MC time = 50 ms). K. Buranapunviwat and K. Sojiphan Materials Today: Proceedings xxx .How to Do Weld Inspection In general, conventional materialographic and hardness testing techniques also apply to weld sections. However, the characteristics of welds introduce some specific challenges for the materialographic preparation.

weld hardness testing pdf

The welding variables are recorded during welding of the test piece and hardness testing is mandatory, the hardness of the test weld HAZ to be less than 248Hv10, that of the weld metal less than an average of 200HBW. Hardness testing surveys are as described in NACE MR0103. In addition to the ASME IX requirements, SP0472 requires butt welds and .

nick break test welding

Figure 5, Typical results from hardness test of a groove weld. Figure 6 shows the detailed pattern for measuring the hardness of a fillet weld geometry. Figure 6, Typical pattern of hardness test of fillet weld. In conclusion Table 1 shows the difference between the hardness test methods discussed and their application, if any, to weldsIncludes a sub-group of hardness testing of welds; Read more about the Vickers hardness test. The Knoop hardness test. Knoop (HK) is an alternative to the Vickers test in the micro hardness testing range. It is mainly used to overcome cracking in brittle materials, as well as to facilitate the hardness testing of thin layers. The indenter is an .Hardness Testing. In weld testing, the term hardness relates to the material’s ability to resist indentation. It is generally done as a non-destructive type of test in a lab. However, you won’t find hardness exams performed in workshops.A hardness test is typically performed by pressing a specifically dimensioned and loaded object (indenter) into the surface of the material you are testing. The hardness is determined by measuring the depth of indenter penetration or by measuring the size of the impression left by an indenter. Hardness tests that measure the depth of .

Welding Hardness test is a type of non destructive test to ensure the integrity of the weld joints. That is performed as per ISO (International Organization for Standardization) standards ISO 9015 and 15614 Specification. But these both standards are not the same, both are used for different purposes. ISO 9015 has two parts, where Part 1 covers hardness testing of arc-welded joints. .

In TMCP steels, a limit is often placed on heat input to avoid undue softening in the weld region, (see Is there a restriction on the heat input that can be used for the welding of TMCP (Thermo-Mechanically Controlled Processed) steels - if so, why?) Reference. BS EN 1011-2:2001 Welding - Recommendations for welding of metallic materials.Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .

As illustrated in Fig.3(b) two diagonals, d 1 and d 2, are measured, averaged and the surface area calculated then divided into the load applied.As with the Brinell test the diagonal measurement is converted to a hardness figure by referring .

Supplementary tests such as CVN test, hardness test, weld macro test & corrosion tests are also used if required by client or specification. Procedure Qualification Record Sample. A Procedure Qualification Record (PQR) is a document that provides evidence that a welding procedure produces welds that meet the requirements of the code or standard . Vickers (HV) hardness test, sometimes called microhardness test only use one type of indenter of pyramid-shaped diamond with different load. Depending on the standards used, HV 30, HV 10, & HV 5 are allowed for . The test is used to determine the hardness of the weld metal. Examine the weld joint carefully to locate the hard area and decide the effect of welding heat on the baseline properties of the base metal drawn.

Methods of hardness testing and mechanical property tests for base metals are covered by ASTM standards or the indi-vidual material specification. . hardness testing and stud weld tests, and organized the tests by weld type. The sixth edition (1998) added six new weld-The hardness testing was performed before and after post weld heat treatment process to identify the changes of the value of hardness. Table-4. Hardness test result. The hardness test results were illustrated as a graph shown in Figure-2. Three specimens show the decreasing on hardness value after PWHT process and cause the lower brittle effect.

Portable Digital Chemical Moisture Meter traders

The document provides guidance on hardness testing of welds in carbon manganese and low alloy steels. Hardness testing indicates the strength and microstructure of welds and heat affected zones. Vickers hardness testing is commonly used, and the results can estimate tensile strength and indicate susceptibility to cracking or plastic collapse based on the microstructure. .

Portable digital Concrete Moisture Meter traders

Brinell Hardness Testing: Involves applying a known load to the surface of the test sample via a hardened steel or carbide ball; Vickers Hardness Testing: Utilises an optical measuring system to measure the area of the impression; Knoop Hardness Testing: Employs a diamond penetrator to impress a sample; A hardness test is a test intended to ascertain the material’s resistance to penetration, abrasion, and indentation. According to the hardness test procedure, the material is subjected to pressure using an indenter type during the hardness test. The Brinell, Rockwell, Leeb, and Vickers hardness tests are the most frequently employed .

Post-weld heat treatment or PWHT is a controlled process that involves reheating the metal below its lower critical transformation temperature, following a welding process. The material is then held at the elevated temperature for a predetermined period of time to alleviate residual stresses, increase the strength, increase or decrease the hardness, and reduce the risk of .This results in a complex microstructure (Fig.1) and a consequent distribution of hardness. In a single-pass weld, the hardness along the HAZ, adjacent to the fusion boundary (grain-coarsened HAZ, GCHAZ) can be described with knowledge of the parent steel composition and the welding parameters (or cooling time from 800°C to 500°C (t 8/5 .

Weld Hardness Test. Hardness testing of welds is usually performed on the polished, ground, or polished and etched cross-section of the joint space. The weld hardness test is useful in providing information about the metallurgical changes caused by welding. For instance, in construction steels, rapid cooling from high HAZ temperature may be the . Testing the hardness of a welded joint is well documented in standards like the ISO 9015 and the ISO 15614. These standards describe test loads, number of indents for parent material, heat effected zone (HAZ) and weld as well as the distances between each indent and the depth below the surface of the welded joint.

how to test weld strength

haplo is a local tool implementation of the same functionality that powers the Ensembl transcript haplotypes view.It takes phased genotypes from a VCF and constructs a pair .

hardness test weld|fracture test for fillet weld